As the automotive industry takes a huge leap and consumer demands for automotive performance and safety standards continue to elevate, SBW (steering-by-wire) has gradually established itself as a pivotal player in the automotive market. According to a forecast by Gasgoo Research Institute, the automotive wire chassis market will see its domestic market soaring to CNY 60 billion, with CAGR of 25.9%, of which the CAGR of SBW accounts for 72.2%.

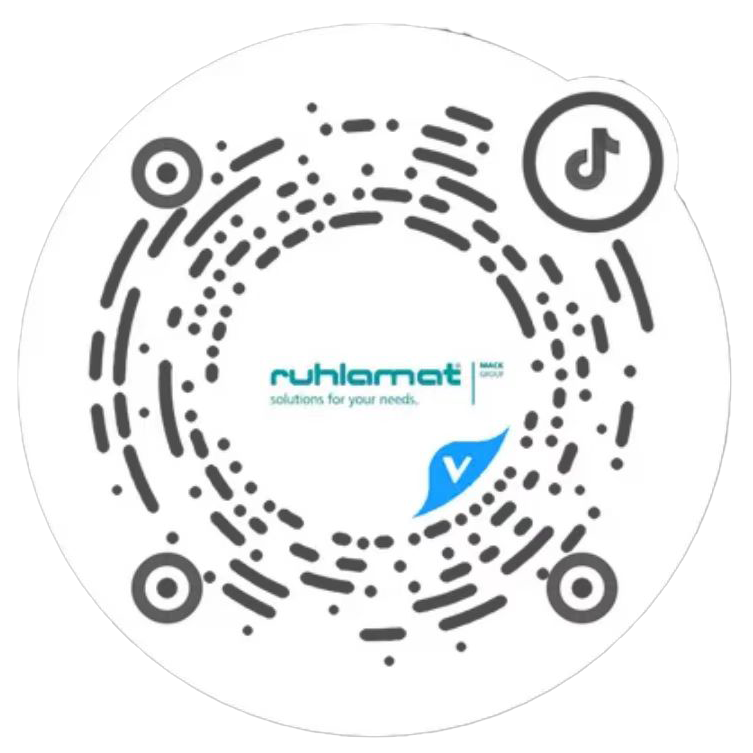

To mark the maiden running of the first made-in-China SBW assembly line, the client’s management gathered at the plant of ruhlamat Suzhou to celebrate the historical milestone with the project team of ruhlamat.

Oliver Buergstein, CEO/ Member of the Board of ruhlamat Asia-Pacific Headquarters, expressed a warm welcome to the clients to celebrate the milestone with ruhlamat.

Liang Chao, COO of ruhlamat Asia-Pacific Headquarters, said that the debut of the SBW assembly line indicates the advanced technologies and market insight of ruhlamat. Going forward, ruhlamat will constantly work to provide outstanding services and solutions to global manufacturers with a devotion to innovation and development.

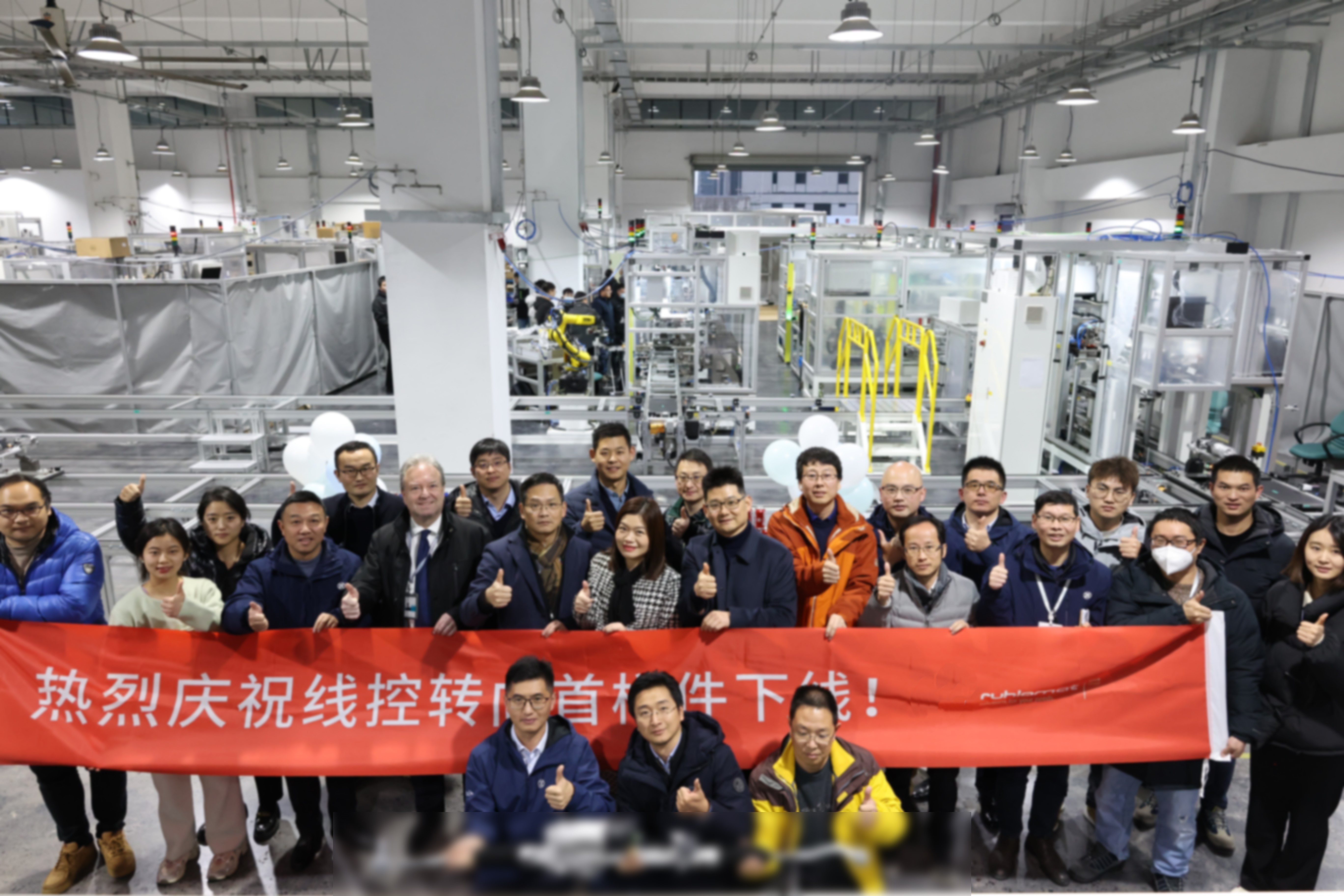

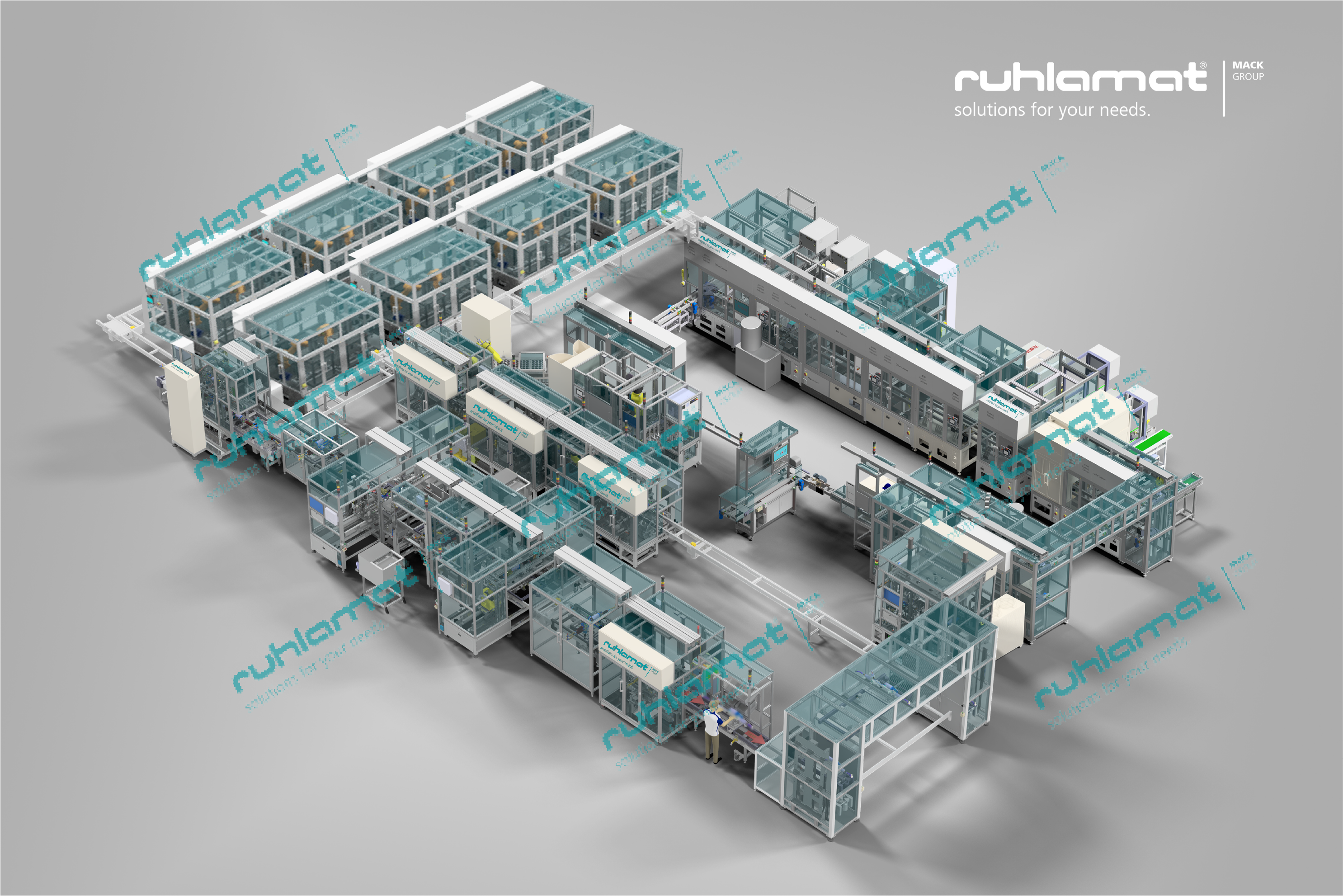

SBW Assembly and Test Line

With the CT of 45s, the line works to assemble and test SBW, empowered by processes of small gear automatic assembly, sensor assembly, exterior and interior tie rod assembly, electric potential, etc.

Turntable with Innovative Design to Realize the Efficient Transfer of Material

· assembly of small gear to effectively reduce the number of equipment and ensure accuracy and steadiness;

· The collaboration between the robot and screw feeder enables functions including automatic identification, greasing and screwing to decrease artificial errors and pollution;

· The automatic assembly and testing are realized by servo press and camera to guarantee the accuracy of pressing.

Two-in-One Production Line to Improve Flexibility

· SBW and BD are in one production line to decrease the initial investment and build a solid foundation for future development;

· The THC pre-assembly of BD is realized to further facilitate the product line.

Digitalization Solution

· The full cycle is on track which is empowered by MES system to achieve data connectivity.